- #Thermal labeller install

- #Thermal labeller drivers

- #Thermal labeller driver

- #Thermal labeller portable

- #Thermal labeller free

#Thermal labeller driver

Mac or Windows Compatibility: Please note that the installation driver of mac, needs to go to homepage to download, working with XP, Win7, Win8, Win10(or newer) and Mac. This is the easiest and easy to understand and will not cause you too much trouble.

#Thermal labeller free

The free U disk comes with all the installation videos and drivers.

#Thermal labeller install

We compare all the ways to install the driver.

It’s easy to get you to start and set up.

#Thermal labeller drivers

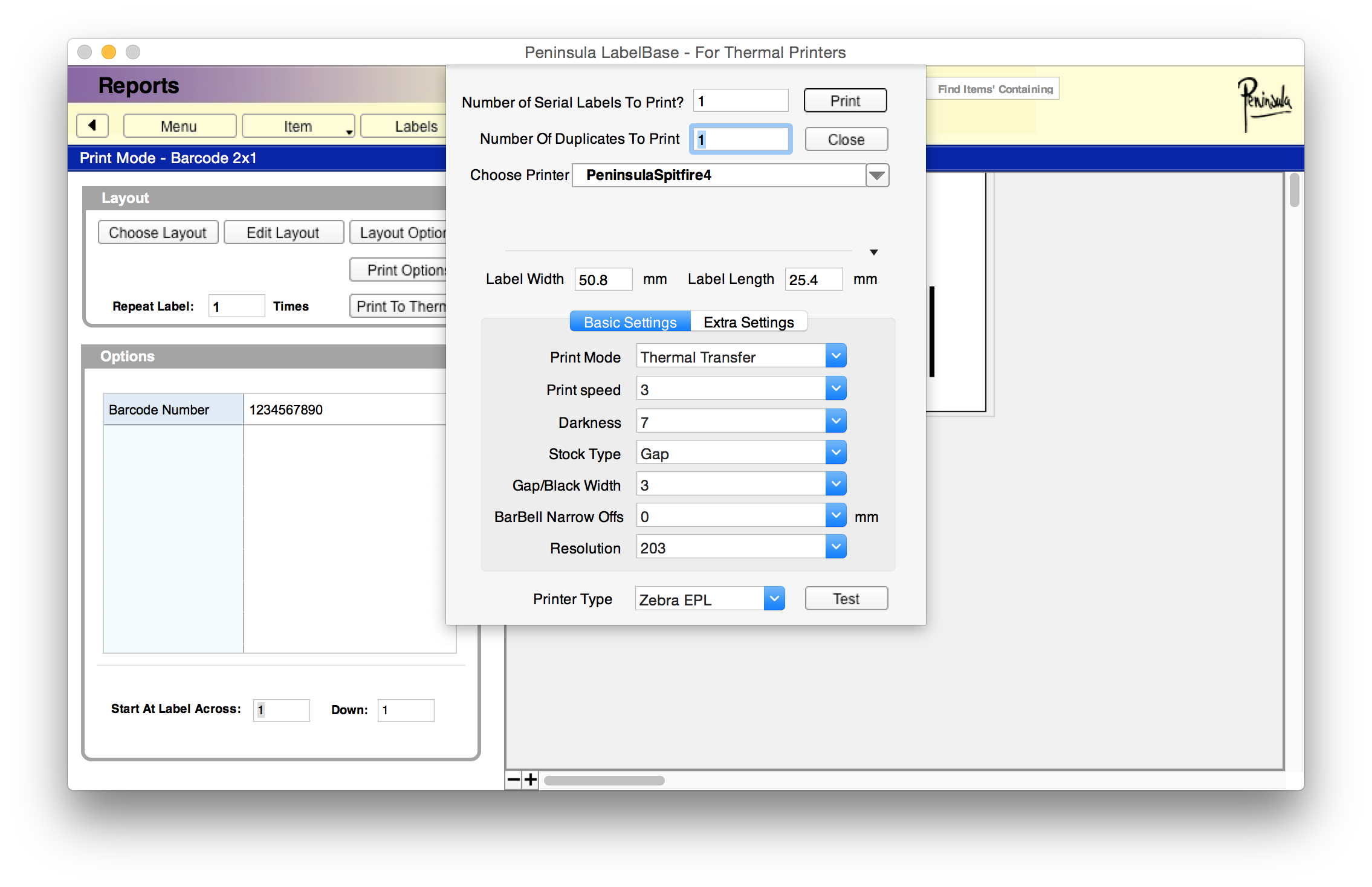

It delivers 203DPI resolution for high-quality print, whether you want to print bar codes, texts or graphics in high quality, this machine will address your needs.Įasy Installation Steps: Come with a unique USB disk which has included drivers software(for Windows and Mac), setting guide and quick start video. Advanced Thermal Direct technology prints without requiring toner or ink. Save Your Time: High-Speed Printing at 150mm/s (one shipping label per second). It works with most direct thermal labels and print labels up to 4" width, suitable for most Thermal Direct Labels - Amazon FBA Labels, Shipping labels, Food Nutrition Labels, UPS, USPS,etc. All you buy is the printer itself and the labels.

Disadvantages of these labels include a short lifespan and extreme vulnerability to heat and light.

#Thermal labeller portable

Direct thermal printers are also portable and do not require the purchase of ribbons. Advantage of using direct thermal labels is that the printing equipment is inexpensive and takes up very little space.When exposed to heat, these capsules burst, creating an image on the label. This stock is coated with material that contains microscopic capsules of ink. The answer lies in the specially formulated paper stock used by direct thermal printers. Why do direct thermal labels turn black when you scratch them? If not, it will be a thermal transfer label. If it turns black, it’s a direct thermal label. Next, run your fingernail or a pen cap quickly back and forth across the label. First, lay the label on a hard surface such as a desktop. If you’re not sure if a label is direct thermal or thermal transfer, try the “scratch test”. Their durability also makes them appropriate for cold storage and outdoor applications.

Thermal transfer labels are used for permanent solutions such as product identification, asset tags, tickets, and certification labels. A label produced with the thermal transfer method will not blacken when a fingernail or other hard object is drawn across it. This method can accept a broader variety of “regular” label materials, including paper, polyester, and polypropylene. Unlike direct thermal, thermal transfer does not rely on a special heat-activated substrate. If the label blackens, it’s direct thermal. One simple way to identify a direct thermal label is by using your fingernail and scraping it across the labels. However, this lifespan is sufficient for numerous applications, such as shipping labels, visitor identification slips, receipts, and ticket printing. Even if stored away from extreme elements, direct thermal labels typically remain scannable for only about six months after printing. Over time, the label begins to darken and the image becomes faded. Labels printed with a direct thermal printer do not stand up well to heat and light. How Do I Tell The Difference Between Thermal Transfer and Direct Thermal Labels?ĭetermining whether a label is thermal transfer or direct thermal is easy.

0 kommentar(er)

0 kommentar(er)